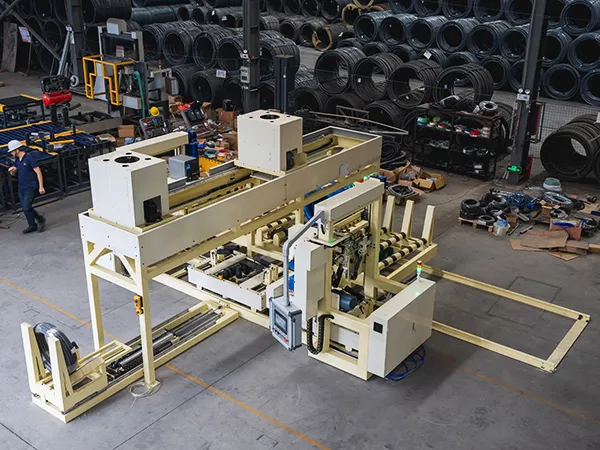

The vertical wire coil packaging line is designed for wire manufacturers and cable producers operating in facilities with limited floor space. This coil packaging system wraps metal rod coils and slit coils in a vertical position, with the eye facing sideways ("eye to side/wall"). Its compact vertical layout minimizes footprint, allowing for optimal use of factory space without compromising packaging performance.

We offer customized equipment configurations based on your coil sizes, production volume, and facility layout, ensuring a tailored solution that maximizes both space and efficiency.

Applications

Suitable for through-the-eye wrapping of ring-shaped metal wire products such as stainless steel, low-carbon steel, high-carbon steel, galvanized wire, copper strip, copper wire, aluminum strip, and iron wire.

-

- SA-LS-400 Automatic Vertical Wire Coil Packaging Line

- Packaging speed: 1.5min/pc

- Inner diameter of coil: 480/750mm

- Outer diameter of coil: 700/1100mm

- Coil length: 200/350/250/170mm

- Weight: 100-300kg (other models are available for weight below 100kg)

-

- SA-LS-35 Automatic Vertical Wire Coil Packaging Line

- Packaging speed: 1min/pc

- Inner diameter of coil: 520mm (±20mm)

- Outer diameter of coil: 700mm (±20mm)

- Coil length: 350mm

- Weight: ≤150kg

- High productivity with a cycle time of approximately 1.5 minutes per coil, delivering stable and efficient automatic wrapping

- Reduces labor costs by over 85% and packaging material usage by up to 30%

- Integrated automatic weighing, label printing, and application, with direct connection to ERP systems for error-free reporting and data management

- Controlled by a PLC programmable system with an intuitive HMI interface

- Compatible with a wide range of coil sizes and materials, supporting diverse production needs

- Selectable manual and automatic operation modes for flexible use

- Automatic adjustment of strapping length and coiling cycles based on entered width, inner diameter, and outer diameter

- Supports custom packaging material selection and adjustable strapping settings

- Automatic alarm system for error detection and fault alerts

- Built with a dedicated control cabinet and a structural steel frame for durability

- Vertical structure minimizes footprint and makes it ideal for space-constrained facilities