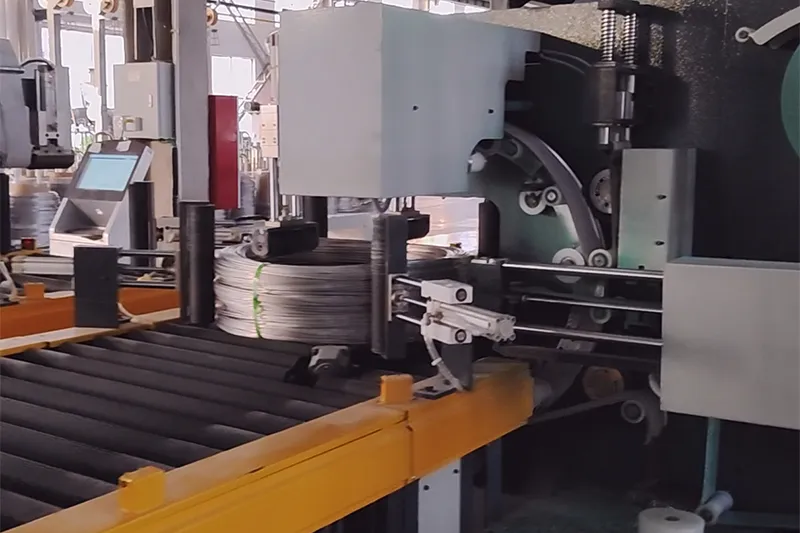

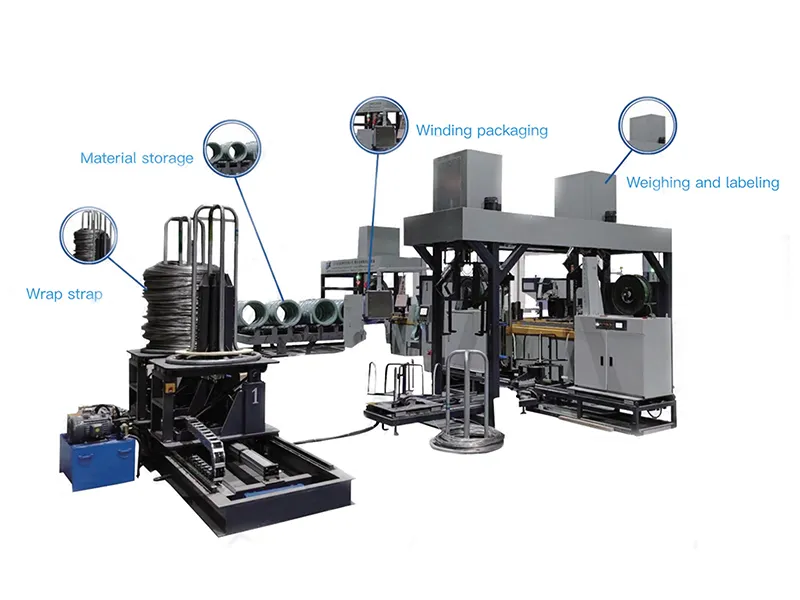

The horizontal wire coil packaging line is a fully automated solution designed for comprehensive handling and packaging of wire rod coils and slit coils. Engineered to minimize labor dependence, the coil packaging system requires only one operator for loading, with all other processes executed automatically.

Once coils are loaded, it performs coil tipping (rotation for proper alignment), automatic strapping, coil wrapping, weighing, label printing and application, and automated storage all in one continuous workflow. Label data is seamlessly uploaded to the customer’s ERP or MES system, enabling real-time data integration and production traceability. By eliminating the need for manual strapping and reducing overall operator involvement, the coil handling and packaging system significantly lowers labor costs while maintaining high efficiency and consistent packaging quality.

Transforming Coils: From Exposure to Protection

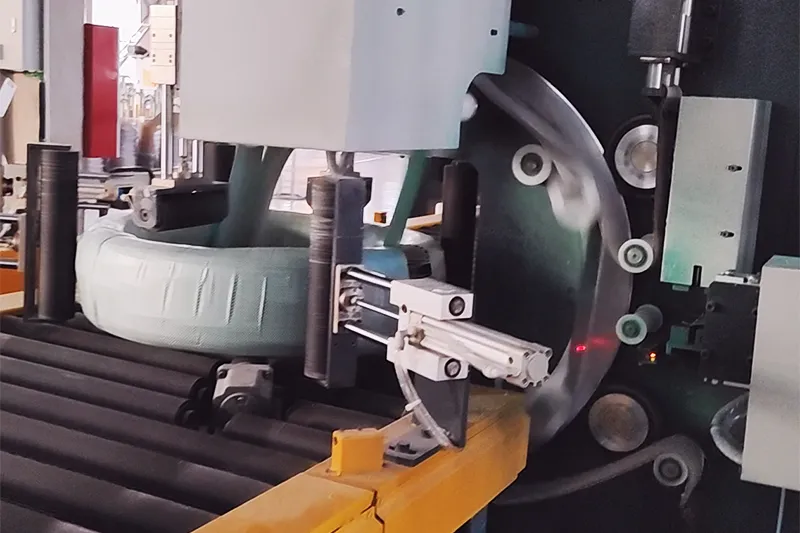

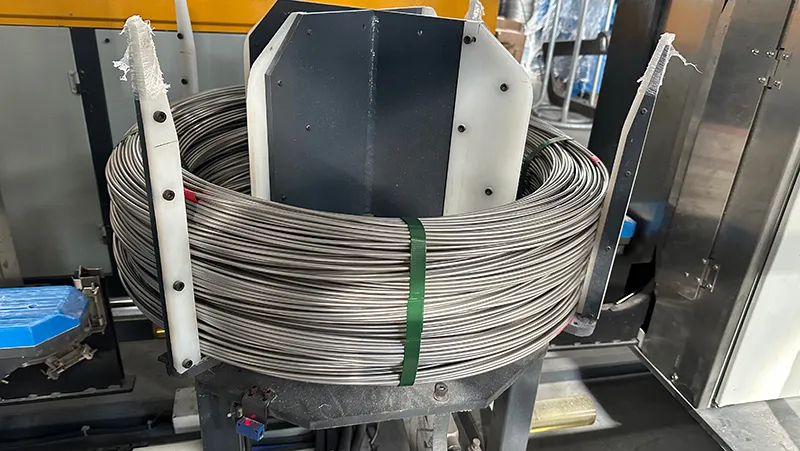

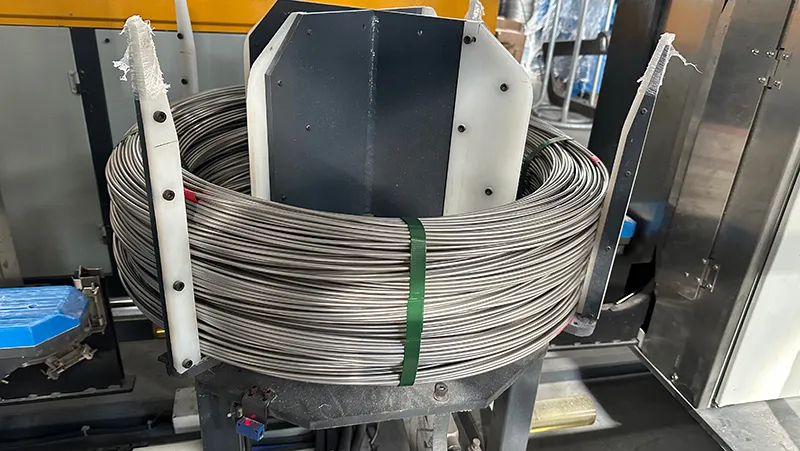

Before packaging

Before packaging

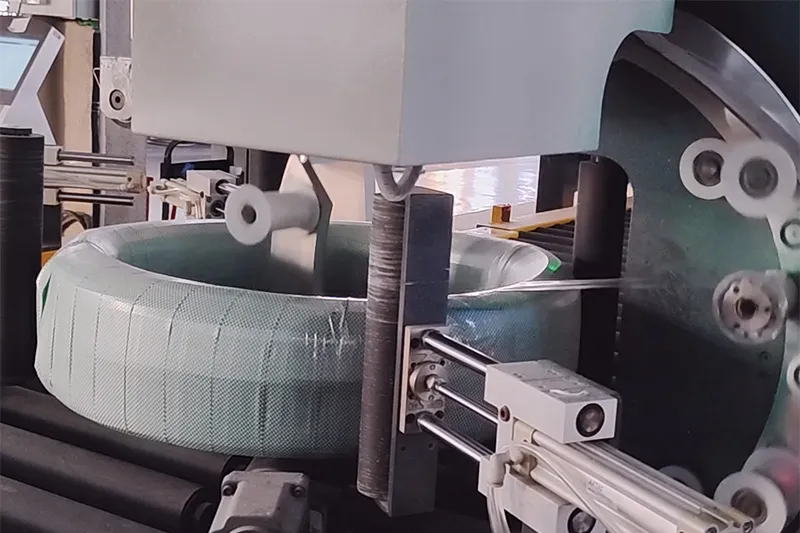

After packaging

After packaging

Features

- Reduces packaging material usage by approximately 30%

- Equipped with automatic alarm system for fault detection

- Operable by a single person, significantly reducing labor requirements

- Horizontal structure ensures lower center of gravity and greater stability compared to vertical models

- Compatible with AGV automatic feeding, enabling fully intelligent operation

- Supports remote monitoring and control

- Allows flexible selection of packaging materials and adjustable wrapping configurations

- Fitted with Siemens electrical components for reliability

- Fully customizable dimensions based on your coil sizes and packaging requirements

- High structural stability with a wide base and low center of gravity, enhancing vibration resistance and making the machine easier to operate and maintain

Optional

- Coil centering, weighing, and coiling

- Material conveying and packaging

- Real-time labeling

- Material classification

- Temporary product storage

- Data input for integration and traceability

- Automated unloading

The packaging speed typically ranges from 45 seconds to 1.5 minutes per coil, depending on the material, size, and type of packaging material used. Speed settings can be adjusted to match your production needs for optimal efficiency.

In addition to the standard manual loading, we offer a range of options including AGV automated feeding, forklift loading, and overhead crane feeding. These options allow for greater automation and adaptability to your facility layout and workflow.

The horizontal structure provides the wire coil packaging line a higher stability due to its low center of gravity and broad base. Compared to vertical systems, it is less prone to tipping, offers better vibration resistance, and is easier to operate and maintain, making it a reliable choice for continuous operation.

Related Coil Packing Lines

Before packaging

Before packaging  After packaging

After packaging